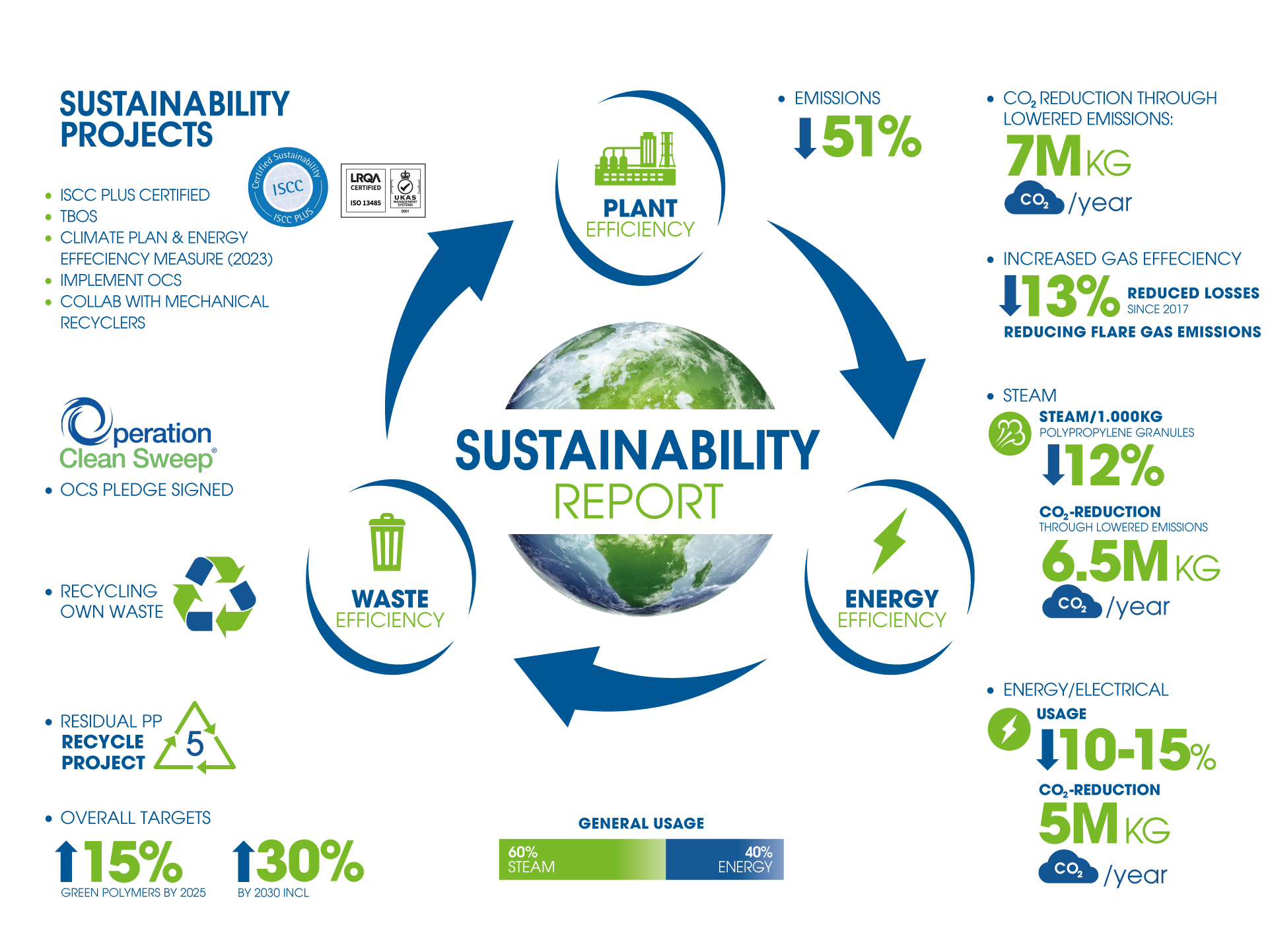

SUSTAINABILITY PROJECTS

Ducor Petrochemicals has always been conscious of sustainability. We feel it’s required, being a part of such a major player in the petrochemical industry. We have a responsibility not only to people and profit, but to the planet.

PLANET

Ducor always strives to be environmentally friendly, and to be ever more economical with raw material and energy usage.

PEOPLE

Ducor endeavors to make products with respect to the neighbors, employees, suppliers, subcontractors and the rest of the community.

PROFIT

Ducor seeks profitably in order to invest in sustainable production practices, as well as to decently compensate employees, suppliers and shareholders.

What are the Ducor Sustainability Projects?

Our work is far from complete. We continue to reduce our steam and electricity footprints. With the same drive and ambition that we have for plant efficiency, we will also work on ways to sustainably recycle waste and water. These changes will cultivate a better future for generations to come.

We have summarized this plan in our Ducor Sustainability Projects. Each year we present initiatives that have been completed in the previous year, including the ecological preservations that have been realised.

Together with our partners, we anticipate, transform and evolve toward a sustainable future.

PLANT EFFICIENCY

PLANT EFFICIENCY

51% REDUCTION IN EMISSIONS

Ducor invested a lot of time, energy and money to increase plant efficiency. The result? A top performance: we reduced emissions by 51% compared to previous years. This surpassed Ducor’s goal, and yet Ducor remains focussed on further increases in efficiency.

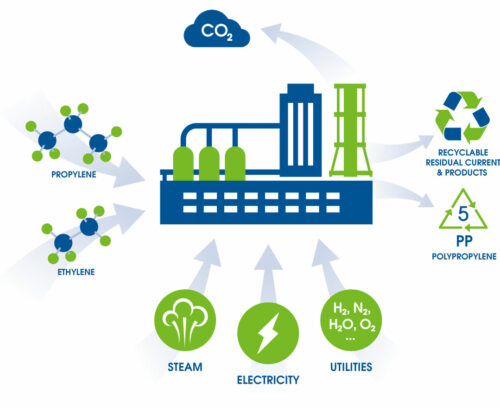

This result is an example of the increase in overall plant efficiency. In theory you should get 1kg of polypropylene granules from 1kg of propylene. However, in practice it is difficult to achieve 100% efficiency at every step of the process, so in reality, closer to 0.99 kg remains. The residual gasses are burned in a flame-installation to prevent flammable glasses from being dangerously released into the atmosphere. The PP production process itself is environmentally friendly, it is the residual gasses that account for nearly all the plant’s CO2 emissions.

Concrete initiatives & Plant Efficiency Projects

- ISCC PLUS certified

- TBOS

- Climate plan & Energy efficiency measure (2023)

- Implement OCS

- Collab with mechanical recyclers

We aim to increase gas efficiency to 100% to lower the impact on the environment. The more efficient our processes, the fewer raw materials and less energy we require, further resulting in a lowered impact on the planet

ENERGY EFFICIENCY

ENERGY EFFICIENCY

Our plant draws on raw materials and energy. Energy is broken down into subcategories, not unlike it is in the home: gas, water and electricity. Ducor uses electricity not only for the lighting, but for the propylene pumps and compressors.

One of the goals of the Rotterdam Climate Accord is sustainable electricity. This is to be accomplished largely by solar panels and windmills as well as other sustainable solutions.

For Ducor this means our primary energy reduction focus lies in steam usage.

Instead of gas heating, Ducor uses steam. This steam is purchased from a steam producer who burns gas in order to create it, and therefore emits CO2. In other words, steam consumption is also indirectly associated with CO2 emissions.

STEAM

STEAM

Ducor worked actively to reduce its steam usage. Steam usage is expressed in terms of the quantity of steam needed to produce 1 ton (1,000 kg) polypropylene granules.

The quantity of steam needed to produce 1,000 kg polypropylene granules was reduced by 12%.

Expected CO2 reduction on steam usage:

ELECTRICITY

ELECTRICITY

We try to reduce electricity usage, even when it’s from a sustainable source. The electricity that we conserve can be (used by others, or can prevent more windmills being built than is necessary.

We are currently working on a project to reduce energy/electrical usage by 10-15%.

Expected CO2 reduction:

Furthermore, Ducor had a study conducted to determine how and where we can conserve energy. The KWA Business Advisors’ Energy Reduction Feasibility Study reported that “The study concluded that the minimum energy usage has already been achieved.” Ducor will continue to carry out studies for future improvements.

WASTE EFFICIENCY

WASTE EFFICIENCY

During the production of polypropylene, residual products are created. These byproducts are a result of the reactionary process, or are waste products that remain after cleaning.

- Research was begun with Deltalinqs to find a third party to make use of Ducor’s byproducts.

- Residual PP recycle project.

ELECTRICAL vs FOSSIL FUEL USAGE